design | recycled countertops

Old Countertops can be made new again with a good fabricator and just a touch of gold! Check out how I recycled my Quartz Countertops, and what I learned from the process.

Everything Old …

When originally deciding what to do when our Range was dying and the cabinets were falling apart, I tried pretty hard to keep the original (Silestone) Quartz Countertops. Even White, they really had stood the test of time over 18 years and were in great shape, but in the end it just wasn’t going to work with the new layout. So I started looking at ways to make sure they would have a good home.

I tried calling Construction demo places to see if they took old Countertops for new projects, and even called the City dump to make sure if they were tossed they would eventually be recycled. No clear answers resulted. I’m still wondering what happens to all that waste every time an old Kitchen is laid to rest… But I decided only the smallest portion of mine would ever find out.

The BEFORE shot - things were getting pretty sloppy pre-demo!

The Art of Kintsugi

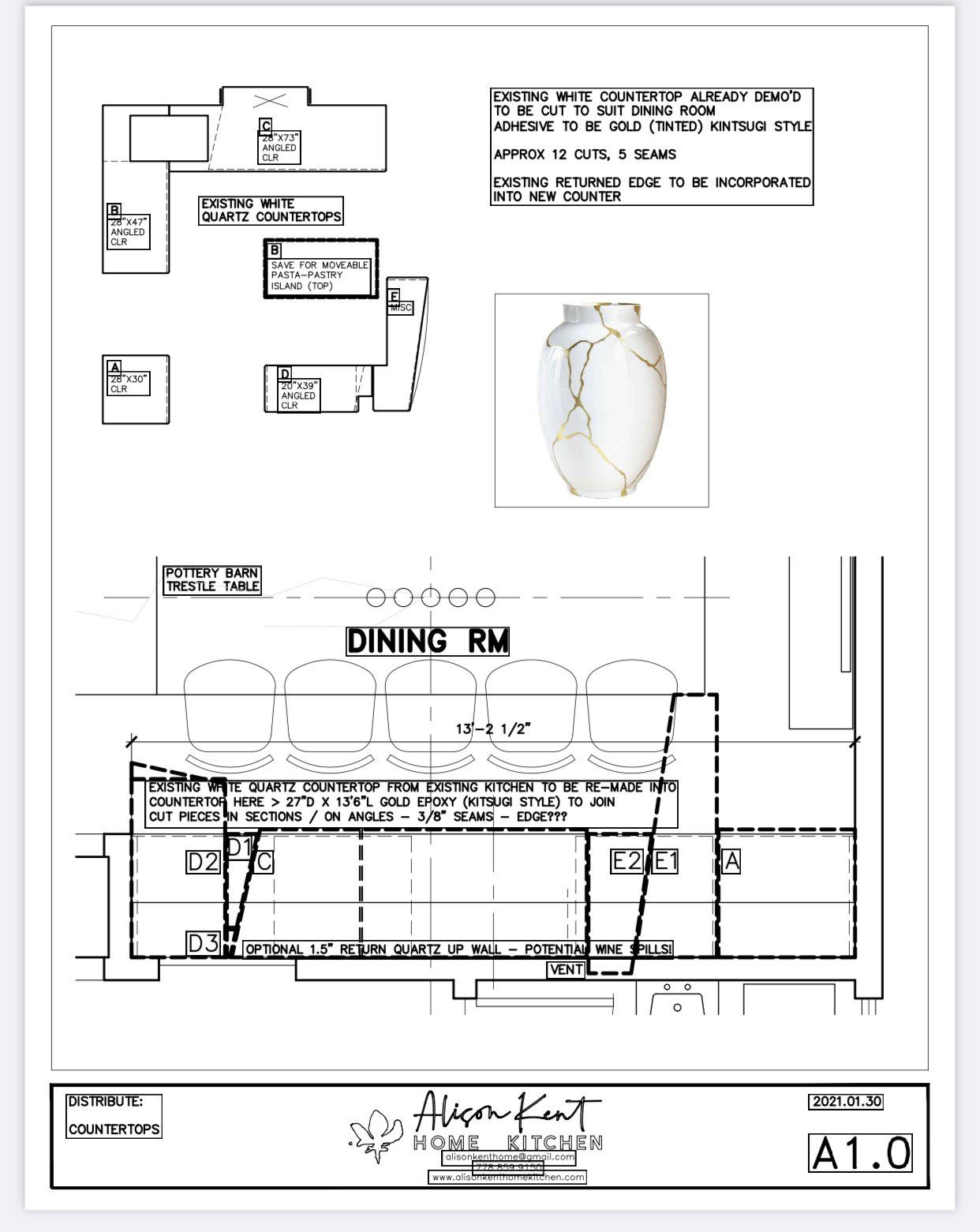

A piece of Plywood with vinyl ‘Marble’ sticker had been holding down our Dining Room counter for some time until I was ready to make a decision on what to do, and I started to wonder if it might be the perfect place to ‘re-use / recycle’ and re-install the Old as New.

Even with plastic sticker, the Dining Room is taking on character with our old Pottery Barn trestle table, Beastie’s new home between cabinets, hand-drawn Utensils wallpaper in the cabinets, and the antique Mirror I found at a vintage shop!

For some years I had been fascinated by Kintsugi, the Japanese practice of taking something broken and making it new again by seaming it back together with golden glue. In the end, the ‘New’ was seen as far more valuable than the ‘Old’ had ever been. I had been practicing it whenever a vintage piece of dishware broke, determined not to toss it but to give it a different, more precious life. Maybe now instead of holding potatoes, it would hold jewelry.

I didn’t know exactly how this idea would translate into a Countertop, but knowing that this particular area wasn’t in a ‘wet zone’, I thought it would be a safe place to give it a try.

‘NO’ is Not in my Vocabulary!

I spoke about the idea to MULTIPLE Countertop fabricators, and a) no one seemed to understand what I wanted to do, b) their response to something they didn’t understand was to tell me I didn’t actually want it LOL, and c) the result of every conversation was … NO. Too messy, too hard, too expensive, too odd, too risky - it’s just not how things are done.

But, I’m stubborn. And relentless. And eventually one guy reluctantly said he would come by for a day, with no promise of it working out. I was elated.

Just needs a good cleaning, and they’re ready to go …

Measure Six Times, Cut Once

The day he showed up, I had measured and re-measured to make sure there were enough pieces of the right size to puzzle back together in the Dining Room. He re-measured again, we talked about what to put where, how it was all going to (hopefully) work, and how to support it all, and away we went!

Each piece was triple checked in the Dining Room, and plywood cut to support it all off the Cabinets for the protection of the top of the drawers and the finger pulls.

The Learning Curve

More trials - trying to determine where the Plywood should go, making everything level. In future I would have the existing wood removed from the old Countertop, and pre-paint/edge a piece of 1/4” or 3/8” MDF (not the 3/4” shown that I used). These millimeters would be figured out on a project-by-project basis once the existing conditions of everything are determined.

As each piece was carried out by hand, the largest one dropped and cracked in half! The Fabricator was crushed - but I was celebrating. THIS was the detail I had wanted all along, not the nice, even cuts we (mostly) had. It’s by far my favorite part of the ‘New’ Countertop and I secretly wish we had broken more pieces…

I carefully saved every chip to put back in place back in the Dining Room! Thankfully the Fabricator was game to patiently put it all back together chip by chip.

That beautiful, ‘natural’ breaking point!

All that Glitters

Hard at work gluing every puzzle piece into place! Between the perfectly straight hand-cut lines and the curvy broken bits, the Quartz was seamed consistently. I had looked into adding a gold dust compound to the glues he was using, but they didn’t arrive in time and this day was my one chance to get it done. Next time I would definitely start with gold dusted epoxy, then touch up.

Next up since I didn’t get the gold dust in time, I added my own touches of Gold at the seams. The hand-cutting leaves a slightly rough edge, but after a few rounds of paint and a sealant, I made it as clean as possible with a razor edge.

Professionally cut in and glued in-shop would be much cleaner. IF it was possible, I would have measured every piece with painter tape and sent it to the Fabricators shop for the laser machine. It’s all part of figuring out something new. I still love it, though - the character, the salvage, the ‘old made new’, the story it tells, the connection with our first Kitchen …

These beautiful cracked bits! Love this part of the Counter!!!

The Tips & Tricks

I researched for MONTHS and could not find information on recycling Quartz with Kitchen Design. Which is too bad - I was hoping for advice. But I'm not above making all the mistakes myself in order to refine an idea. I think this is a great solution for >

Recycling - especially if your original material holds meaning to you or is in decent condition / has a beautiful patina

One big, beautiful clean seam as a Design feature when your Island is bigger than the slab sizes (or the elevator…)

An countertop/backsplash Design feature in general just because it’s more interesting than not!

... Where can you imagine using metallic seams as a feature?!

Here also are my solutions for some of the challenges I found on this first trial ...

1. A hand saw creates jagged edges on the cuts (on the top face). For precise cuts, make your measurements CLEAR with painters tape and let a Fabricator cut it in shop

2. If you are bound by a very specific dimension/walls, the very end edge that sits against a wall can be cut on site by hand if needed

3. If you love the look, let it break! The piece that fell and smashed made the most beautiful design (albeit much more work to seam)

4. Use only 1/4" plywood/MDF to mount onto if you have multiple seams that could use support - we used an old (recycled!) 3/4" ply and it's far too fat. I painted the visible edge white, but … I still notice it.

5. Add gold powder to the seaming glue to your liking - ensuring it's 'glue compatible' and won't turn green over time - or copper - or silver - or …

6. Save any other small pieces and have edged for Hot Trivets, Charcuterie 'Boards', Dresser Tops, Garden Stones, and so much more ...thehomekitchen.com

AND … <drumroll> Everything Old Becomes New Again

And - VOILA!

What do you think??! Let me know in the Comments!!

While it’s not perfect, it’s exactly what I had wanted to try, and it was the perfect place in which to test it. I believe with a professionally applied gold sealant, it would do well on even a wet-zone Countertop as a way to re-use old pieces, or to artfully make an Island top larger than a Jumbo sized piece of Marble or Quartz, or to create (should someone want to) a Mosaic of sorts.

I still don’t know EXACTLY what happens to Quartz once it’s demolished from a site for a Reno - and no one else seemed to definitively know either, regardless of the recycle hype - but I do know this is one Countertop that’s leading to solutions in recycling instead of the landfills.